Swann Rack / Holocreators In the workbench ”Part Design” click on “Revolve a selected sketch”. Swann Rack / Holocreators When all constraints have been defined, the sketch will turn to green. Aįrequent change between Netfabb and FreeCAD is necessary until all constraints are defined for the Swann Rack / Holocreators Define the dimension between the edge of the flange and the center. Swann Rack / Holocreators Click on “fix a length of a line or the distance between a line and a vertex “. Swann Rack / Holocreators Design on the cross-section of the flange. Swann Rack / Holocreators Select the XY layer. Swann Rack / Holocreators Click on “create new sketch” to enter the ”sketcher” workbench. Swann Rack / Holocreators If CTRL+D does not work, you can set the “Transparency” directly in the menu’s lower-left handĬorner. Swann Rack / Holocreators The key combination CTRL+D opens a window in which we can set the “Transparency”. Step 3: Change the Transparency of the 3D Scan in FreeCAD and Create a ProfileĪdjust the 3D scan to make it semi-transparent to allow for designing directly on it.

This will simplify the CAD modeling process. Now optimally aligned in the FreeCAD coordinate system. Swann Rack / Holocreators Finally, switch to a top view and move the 3D Scan until it is in the center of the circle. Swann Rack / Holocreators Change the view and repeat the process for the Y-axis. Swann Rack / Holocreators In the end, it should look like this. Swann Rack / Holocreators Switch to a side view and rotate the 3D Scan incrementally until it is aligned perpendicular to the Xaxis. Swann Rack / Holocreators Activate the checkbox “Apply incremental changes to object placement”. Swann Rack / Holocreators Click on the three dots next to the “Placement” button. Swann Rack / Holocreators In the lower-left hand corner, click on the button “Data”. This is done in the “Sketcher” workbench.

Step 2: Correct Alignment (Placement) of the 3D Scan in FreeCADĪlign the 3D Scan optimally along the X, Y and Z-axes. The reference circle sketch is now ready. So 76mm/2 FreeCAD will automatically calculate the radius ofģ8mm. Swann Rack / Holocreators Enter the radius of the diameter. Swann Rack / Holocreators Click on the button “Fix the radius of a circle or an arc”.

Click on the button “Create a circle in the sketch”. Swann Rack / Holocreators Import the file “professional-3d-scan-with-artec-space-spider-tankgeber-part.stl” into FreeCAD andĪctivate the workbench “Sketcher”. Swann Rack / Holocreators The outer diameter of the flange is 75.97mm-round up to 76mm. Netfabb will automatically output the outer diameter. Swann Rack / Holocreators Select the outer edge of the flange. The button “3 points on circle” must be activated. Swann Rack / Holocreators Click on “Measure Radius”. Swann Rack / Holocreators Click on the button “New Measuring”.

#USING FREECAD TO CONVERT IGES TO STP DOWNLOAD#

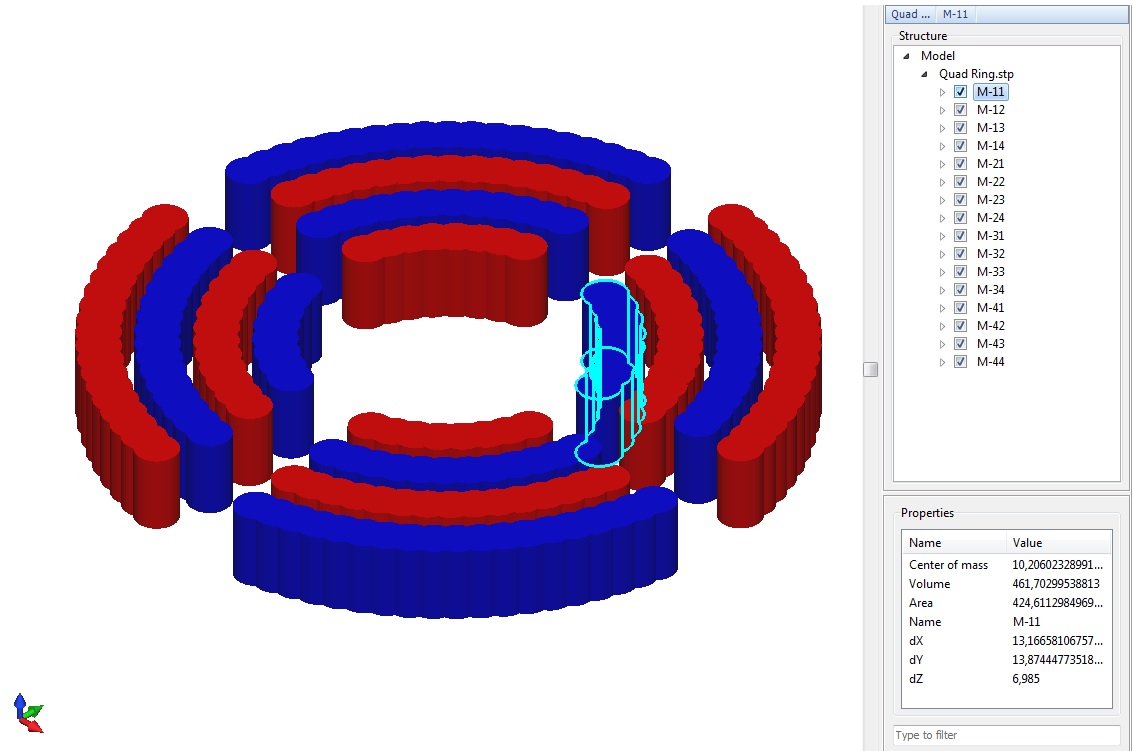

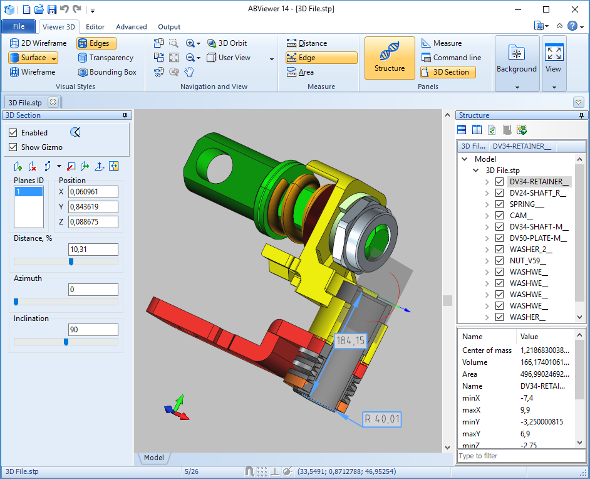

We have prepared the 3D Scan for download here. Swann Rack / Holocreators The original 3D scan is imported,”professional-3d-scan-with-artec-space-spider-tankgeber-part.stl”, In this first step, a circle is defined using FreeCAD, which will help us align the 3D scan correctly. Step 1: Measure the 3D Scan in Netfabb and create a reference sketch in FreeCAD We have prepared the CAD file for download here. Swann Rack / Holocreators After reverse engineering using parametric modeling in FreeCAD, the finished solid model (STEPįormat) looks like this. Swann Rack / Holocreators This is the original 3D Scan (STL format) of the tank sensor part. Then, a reverseengineered 3D scan was created using parametric modeling in FreeCAD.

#USING FREECAD TO CONVERT IGES TO STP PROFESSIONAL#

First, aģD scan was made using the professional 3D scanner, Artec Space Spider. The broken part, which serves as an example project, is a fuel sensor from a 50-year-old car.

0 kommentar(er)

0 kommentar(er)